Production rate estimating will help you convert your expertise into a process that can be used by other team members.

Doing this will help you expand the business and make sure things remain profitable.

An inexperienced estimator joins the team and you know if the measurements and counts are proper your bids will all stay consistent coming from any team member.

Converting from time and material estimating to production rate estimating might seem like a big deal, especially if you typically are doing extremely large projects.

Breaking your project down into smaller segments is going to be key.

As much as I hate clichés here is one…..‘how do you eat an elephant? ……one bite at a time’.

The focus here will be an interior painting project, and from a larger, multi-room project, breaking that down into a single room and then eventually the different substrates in that room (ceiling, walls, trim, door, windows). The different subsections or substrates will be critical in whichever industry you are working.

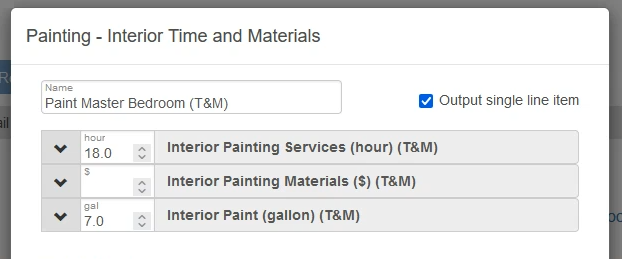

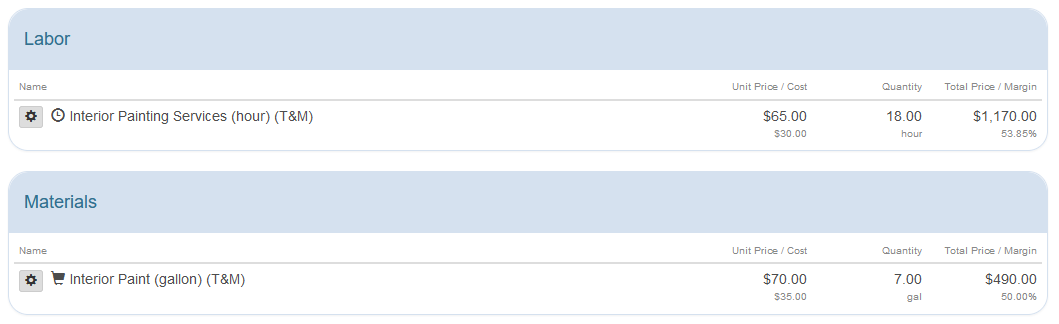

The time and material interior painting estimate for a single room

The time and material estimate uses the knowledge you have about the industry where you can look at a 18 x 22 bedroom for example and know that it will take 18 hours to paint the walls, ceiling, trim, doors and windows. In this case very simple to add 18 hours and 7 total gallons of paint. Notice the material can either be done in gallons of paint or in dollars. In this case I did gallons to compare the number of gallons calculated by the formulas in the production rate section.

The labor and materials that will appear in the work order come directly from the entries in the time and material form.

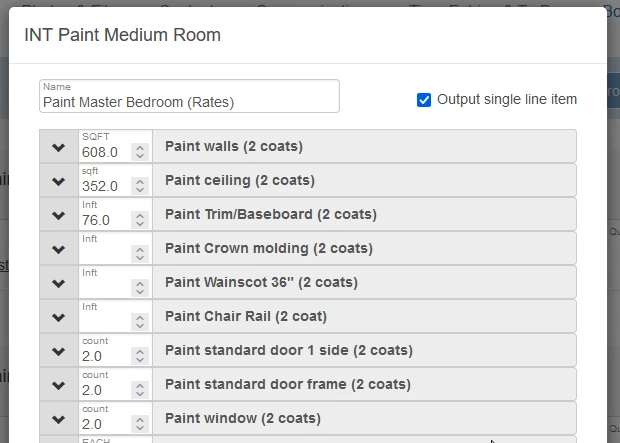

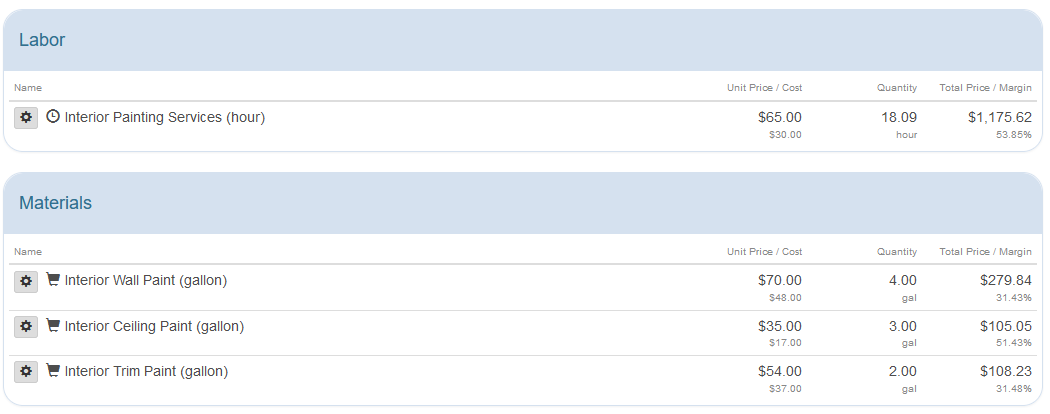

The production rate interior painting estimate for a single room

In this case the estimator would enter the room dimensions and count of items in the room for the production rates to calculate the needed time for the master bedroom.

The labor and materials, in this case, come from the calculations of production rates for the labor and coverage rates for the material.

Balancing the two will dial in the production rates for your organization

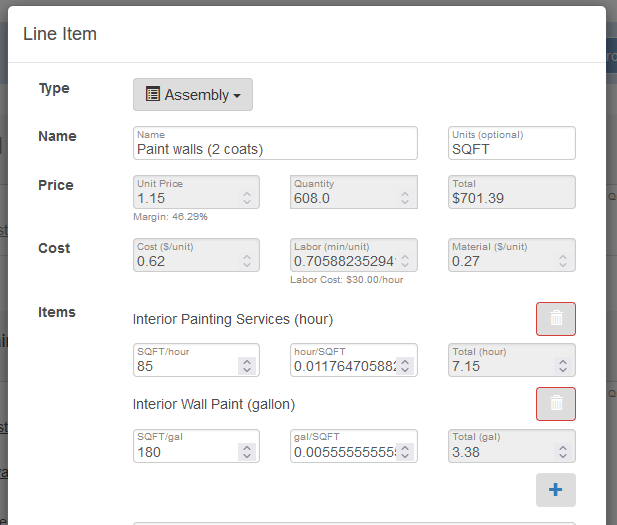

If the labor total does not balance between the 2 methods you will need to adjust the production rates of the calculated items. In the case of paint walls 2 coats you will see the production rate is 85 SQFT per hour. If you think your team would take 8 hours to complete 2 coats on 608 SQFT of walls then reduce the production rate from 85 SQFT per hour until the calculated hours are 8.

Use the project as a calculator to put in a typical room size or even 100 or 1000 SQFT to get a round estimate of time.

Once you make the change at the project (calculator) level be sure to open your item library to make the same change there as well.

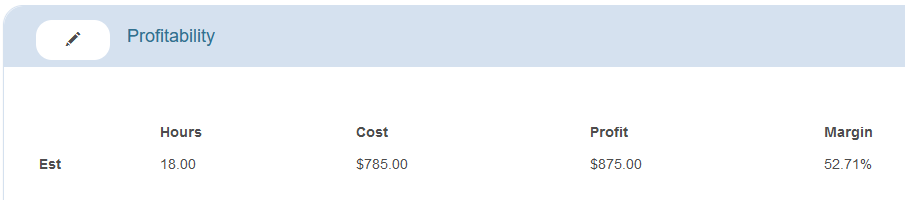

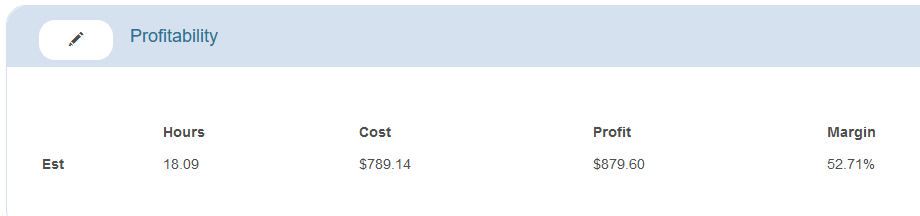

The profitability using either method is easy to compare as well

The labor and materials in both cases have been setup with a similar price / cost structure which is how the profit margin is calculated.

Video comparing the time and material to production rate estimate

Other Interesting Education Articles

Using Project Hours Budgeting to Reward your Employees

Tracking Profitability and Sales in Estimate Rocket

Managing Scope of Work Changes in Estimate Rocket

Sensible Changes to your Profit Margin in Estimate Rocket

Managing Project Completed Free Follow Ups and Follow Up Campaigns

Avoiding Costly Job Rework Using Estimate Rocket Change Order Sign Offs

Accepting Electronic Payments to Improve Cash Flow

The Critical Role of Job Costing In the Home Improvement Contracting Business